Applications

Welding Procedure Development & Qualification

APPLICATION: NATURAL GAS PIPELINE

2 off 12mile long, parallel pipelines to transport natural gas from an LNG Re-gasification plant to an inland Cement Works.

Pipe material specificationAPI 5L X52 PSL2, carbon steel pipe 273mm OD x 6.35mm thick to be welded in accordance with API STANDARD 1104.

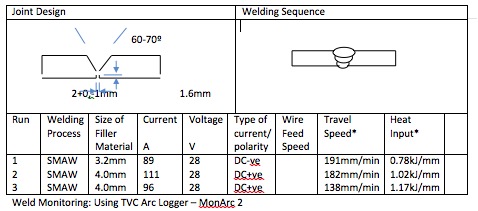

Welding Procedure Qualification Record (WPQR)Code/Testing Standard – API 1104

Welding Process – SMAW (Shielded Metal Arc Welding)

Joint type – Single Vee Butt Weld, Multi run (3 passes).

Maximum pass thickness – 3mm

Filler metal classification – AWS A5.1-04: E6010 Flux type – Cellulosic

Filler metal size – Root: 3.2mm, Hot pass & Cap: 4.0mm

Welding Position – 5G Vertical Down

Welding Current Polarity – Root: DC-ve, Hot pass & Cap Dc+ve

Other information:

External line up clamps removed after 50% of root completedTime lapse between runs – Root/Hot pass 5mins. Hot pass/Cap 15mins.

Mechanical Test ResultsTensile Tests: Rm 524 & 542 N/mm²

Bend tests: Root & Face bends (4T Former) 180°angle – Acceptable Macro examination: Acceptable Nick Break fracture tests (Transweld) – Acceptable.

Hardness Test:

Charpy Impact Test: sub size specimen 3.3mm.

Test temperature: 0°C. Charpy value range (Transweld): 23-51J

Vickers Hardness Test: Hv10.

Parent Metal – 156-175HAZ – 174-216Weld Metal – 169-182

Aluminium problem?

Welding Duplex?

Quality welding advice